HKS bolt in Super SQV Skyline GT-R bov kit

- In stock, ready to ship

- Backordered, shipping soon

Updates for 2026:

We will now include our 51mm BOV block off plug for the vented kits

The re-circ setup will come with our adapters already mounted and include the vented fins.

[Super SQV]

HKS SUPER SQV (Sequential Blow Off Valve) adopts a unique sequential valve structure, and the differential pressure control system delicately realizes pressure control in a wide operating range from low supercharging range to high supercharging range. In addition, the reliefless operation method ensures stable operation against pressure and supports all turbo cars in a new dimension.

- 1. High quality aluminum die cast body

- Uses aluminum die-cast body + silver paint. It has an overwhelming presence and durability in the engine room.

- 2. High rigidity metal die cast valve

- Metal die-cast parts are used for the main part of the secondary valve. In addition to reliable operation, it has also evolved in terms of aesthetic elements.

- 3. Super sound played by triple fins

- The triple fin set in the center of the funnel produces a high-frequency, loud sound. It produces a sharp and powerful blow-off sound. In addition, we have a lineup of special fins as optional parts for sound tuning.

- 1. Reliefless type valve operation

- The operation is more accurate than the conventional push type valve, and a wide supercharging range is realized.

- 2. Primary valve (small)

- When the accelerator is released, the primary valve opens instantly, quickly suppressing the blowback of the turbine.

- 3. Secondary valve (large)

- Due to the sequential system of the dual valve structure consisting of the primary valve and this valve, the optimum blow-off effect is exhibited without relieving a wide operating range from low boost pressure to high boost pressure.

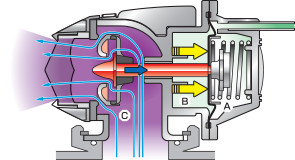

Dual valve structure / sequential method

Due to the sequential system of the dual valve structure that opens the primary valve when the boost pressure is low and the secondary valve when the boost pressure is high, it reacts linearly with good response and exhibits the optimum blow-off effect in a wide range.

-

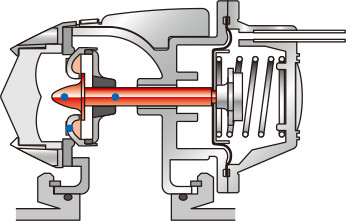

Valve closed when accelerator is ON

Since the chamber pressure is applied to the C chamber, a closing force is generated for both the primary valve and the secondary valve. The higher the boost pressure, the greater the closing force on the valve and the more it prevents relief.

-

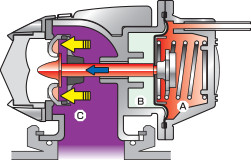

When the accelerator is off,

the primary valve is open

An initial differential pressure (opening force) is generated in chamber B, the primary valve opens, exits the secondary valve, and the primary discharge begins.

-

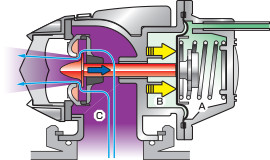

Secondary valve open when accelerator is off

The differential pressure (opening force) in chamber B is maximized, and the primary valve pulls the secondary valve for secondary discharge .

Reliefless type operating method that supports a wide range from normal cars to tuning cars

With the conventional valve actuation method, it is necessary to adjust the set load of the spring according to the specifications of the vehicle. With this operating method, in the case of a vehicle that applies a high boost pressure, if the set load is weak, the boost pressure will be relieved at the time of high boost pressure and will not reach the set boost pressure. Also, if the set load is strong, relief at high boost pressure can be prevented, but it will not operate at low boost pressure.

However, the SUPER SQV is a reliefless type operating method that does not depend on the vehicle specifications, so stable operation can be ensured from low boost pressure to high boost pressure.

Features

- A super SQV4 kit that replaces the genuine air bypass valve.

- Since standard 3-spoke fins are included in the kit, by making it open to the atmosphere, you can hear the sharp operating sound at high frequencies peculiar to Super SQV4, and show a different presence.

- It is also possible to connect to a genuine air bypass hose and make a suction return.