-

Skyline GTR

- UPG Specialty Products

- Muse-Japan

- JHK oil pans

-

OEM Parts

- U.P.G Apparel

-

HKS GOODS & APPAREL

- Garage Sale

- RB26 Tuning Packages

-

The Gallery

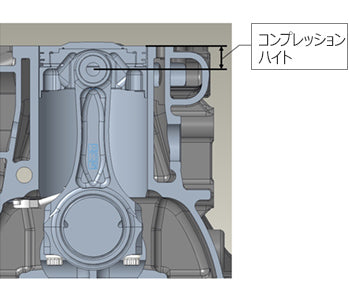

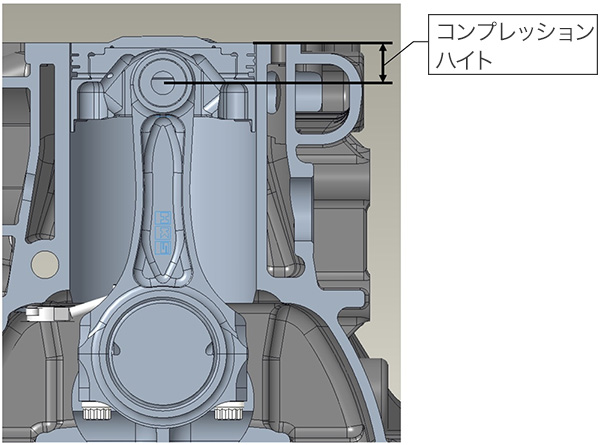

Newly developed 2-piece piston realizes increased stroke and connecting rod length while maintaining block height.

Dedicated full counter crank

Dedicated I-beam connecting rod with 36% higher buckling strength and 6mm longer shaft distance

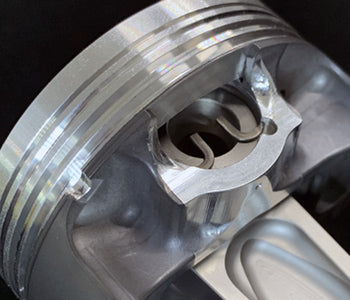

Machined 2-piece piston

By making the piston two pieces and raising the pin position, it became possible to reduce the compression height. This made it possible to lengthen the connecting rod and increase the length of the rod without increasing the deck.

In addition, the piston is super lightweight at 313g and has a cooling channel for oil cooling.

| HKS 3.0L | genuine | |

|---|---|---|

| bore | 86.5mm | 86.0mm |

| stroke | 84.0mm | 73.7mm |

| Compression ratio (t=0.84) | 8.7 | - |

| Allowable rotation speed | 9,000rpm | 7,600 rpm |

| Displacement | 2,996cc | 2,568cc |

| Block (24U) processing details |

Surface grinding (parallelism correction with the main journal), water hole processing, deck surface hole chamfering (crack countermeasures), edge removal processing at the bottom end of the cylinder, boring |

|---|---|

| piston | HKS 2 piece machined |

| piston pin | Φ22 reinforced product |

| connecting rod | HKS I cross section Center distance: 127.5mm |

| Crankshaft | Nitriding steel machined full counter ion nitriding treatment |

| main bearing | ACLs |

| connecting rod bearing | ACLs |